Study of Veneer Yield and Amount of Waste in Veneer Stripping with Spindle-less Type Rotary Lathe Machine

DOI:

https://doi.org/10.51967/tanesa.v22i1.334Keywords:

Waste, Rotary Lathe, Spindle-Less, Veneer.Abstract

In general, the log-block peeling yield on a rotary lathe machine ranges from 70 - 80% of the log volume in the form of veneer, and the remaining 20-30% is waste. This variation depends on the quality and type (species) of the log of the raw material. The veneer peeling usually consist of the face and back veneer (continuous veneer) ranging from 50% to 70% and core veneer as poly piece veneer ranging from 20 to 30%. Under certain conditions, the waste can reach up to 50% including losses due to rounding, shrinkage of the veneer, cracks, spurs, and pith (log-core). From the description above and several other observations, the research was carried out regarding this matter. There is a way to reduce the amount of waste in log peeling using rotary machines and at the same time increasing the recovery peeling. Thus, it will reduce production costs and increase profits for the company. One of the contributors to a large amount of veneer peeling waste is the use of rotary lathe veneer peeling machines with large spindles which are still widely used in veneer and plywood factories (plymill), especially in Indonesia. So far, on average half of raw logs turn into waste, and 25 percent is contributed by a rotary lathe machine. Meanwhile, on the other hand, the need for plywood products will continue to increase day by day. This is because plywood is one of the most environmentally friendly building materials and comes from renewable natural resources. Along with the development of the plywood industry, the increase of raw material needs is inevitable. So, waste products will also continue to increase too. In this regard, there must be fundamental changes in this industry, including the use of rotary lathe without spindles as the substitute from the conventional machine. In relevance to this situation, this research was directed with the aim of knowing the yield and amount of veneer peeled by a spindle-less rotary lathe machine and at the same time to find out the waste it produces. So, this information can later become a consideration for stakeholders to replace the old rotary lathe with a type spindle-less without a doubt. The results show that veneer peeling using a spindle-less rotary lathe machine increases the yield of the veneer and reduce the amount of waste. Most of the peeling results are in the form of a veneer consisting of 58.83% continuous/endless veneer for the face/back, and 22.83% of poly piece core (odd veneer) from the core veneer. The total veneer yield is 81.67%. The remaining were 1.32%, 0.93%, and 16.08% for log-core waste, cut edge finish, and round-up veneer, respectively. The spindle-less rotary lathe machine has provided increased yields and significantly reduced the amount of waste.

References

Baldwin, R. F. 1995. Plywood And Veneer-Based Products: Manufacturing Practices 3rd Edition, Miller Freeman Books.

Bowyer, J. L., Shmulsky, R. & Haygreen, J. G. 2007. Forest Products And Wood Science: An Introduction 5th Edition. Wiley-Blackwell.

Daoui, A., Descamps, C., Marchal, R. & Zerizer, A. 2010. Influence Of Veneer Quality On Beech Lvl Mechanical Properties. Maderas. Ciencia Y Tecnología, 13, 69-83.

Dumanauw, J. F. 2003. Mengenal Kayu, Yogyakarta, Kanisius.

Hrázský, J. & Král, P. 2018. A Contribution To The Properties Of Combined Plywood Materials. Journal Of Forest Science, 53, 483-490.

Khoo, Pui Shan, H'ng, Paik San, Chin, Kit Ling, Bakar, Edi Suhaimi, Maminski, Mariusz. 2018. Peeling Small Diameter Rubber Log Using Spindleless Lathe Technology: Evaluation of Veneer Properties from Outer to Inner Radial Section of Log at Different Veneer Thicknesses. European Journal of Wood ang Wood Products. Springer-Germany.

Kollmann, F. F. P. & Cote, W. A. J. 2012. Principles Of Wood Science And Technology, Germany, Springer-Verlag Berlin And Heidelberg Gmbh & Co. Kg.

Schulte, A. & Schöne, D. 1996. Dipterocarp Forest Ecosystems: Towards Sustainable Management, World Scientific Publishing.

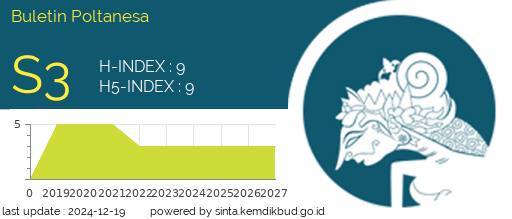

Syafii 2001. Analisis Volumetrik Konversi Kayu Bulat Menjadi Lembaran Finir Pada Industri Kayulapis. Buletin Poltanesa, 1.

Wood, A. D. & Linn, T. G. 1950. Plywood: Their Development, Manufacture And Application, W. & A. K. Johnston.

Downloads

Published

How to Cite

Issue

Section

License

The copyright of this article is transferred to Buletin Poltanesa and Politeknik Pertanian Negeri Samarinda, when the article is accepted for publication. the authors transfer all and all rights into and to paper including but not limited to all copyrights in the Buletin Poltanesa. The author represents and warrants that the original is the original and that he/she is the author of this paper unless the material is clearly identified as the original source, with notification of the permission of the copyright owner if necessary.

A Copyright permission is obtained for material published elsewhere and who require permission for this reproduction. Furthermore, I / We hereby transfer the unlimited publication rights of the above paper to Poltanesa. Copyright transfer includes exclusive rights to reproduce and distribute articles, including reprints, translations, photographic reproductions, microforms, electronic forms (offline, online), or other similar reproductions.

The author's mark is appropriate for and accepts responsibility for releasing this material on behalf of any and all coauthor. This Agreement shall be signed by at least one author who has obtained the consent of the co-author (s) if applicable. After the submission of this agreement is signed by the author concerned, the amendment of the author or in the order of the author listed shall not be accepted.